Example comparison images

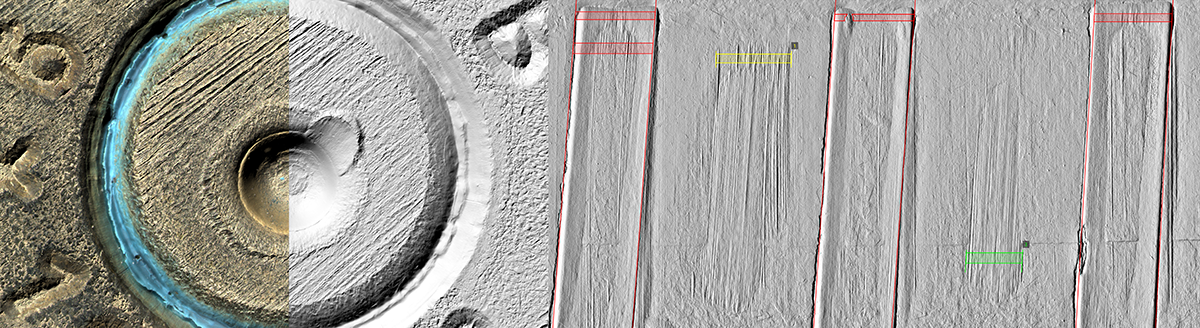

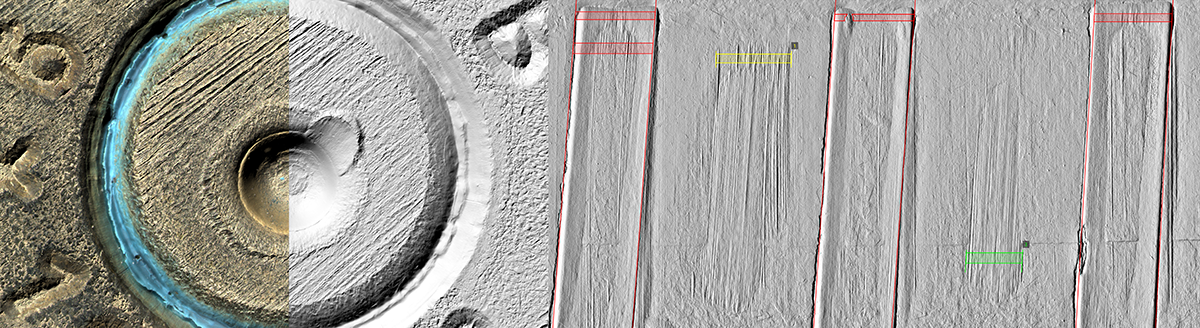

Cartridge case bottom captured by a colour camera (left). Cartridge case bottom (middle). Scanned bullet and processed in ballistic SW (right).

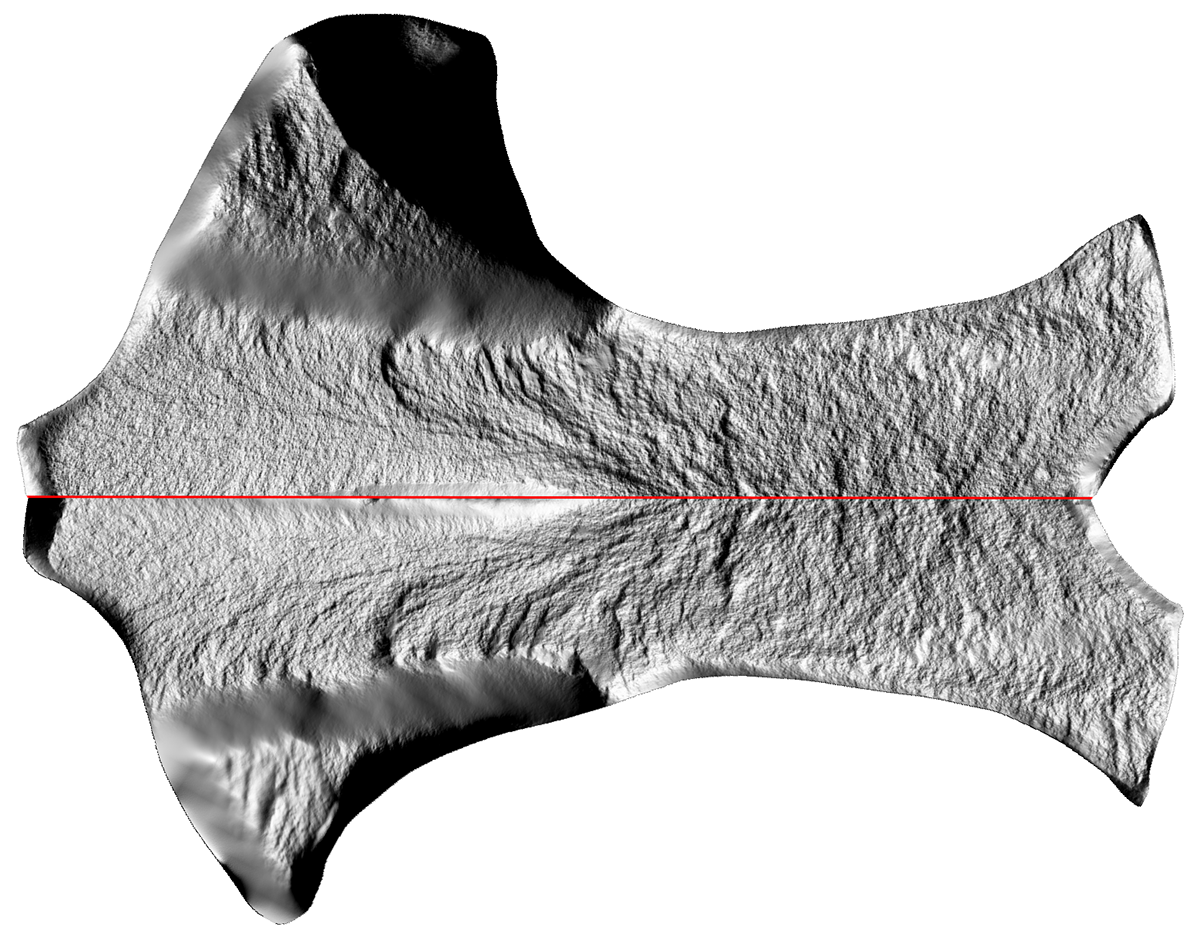

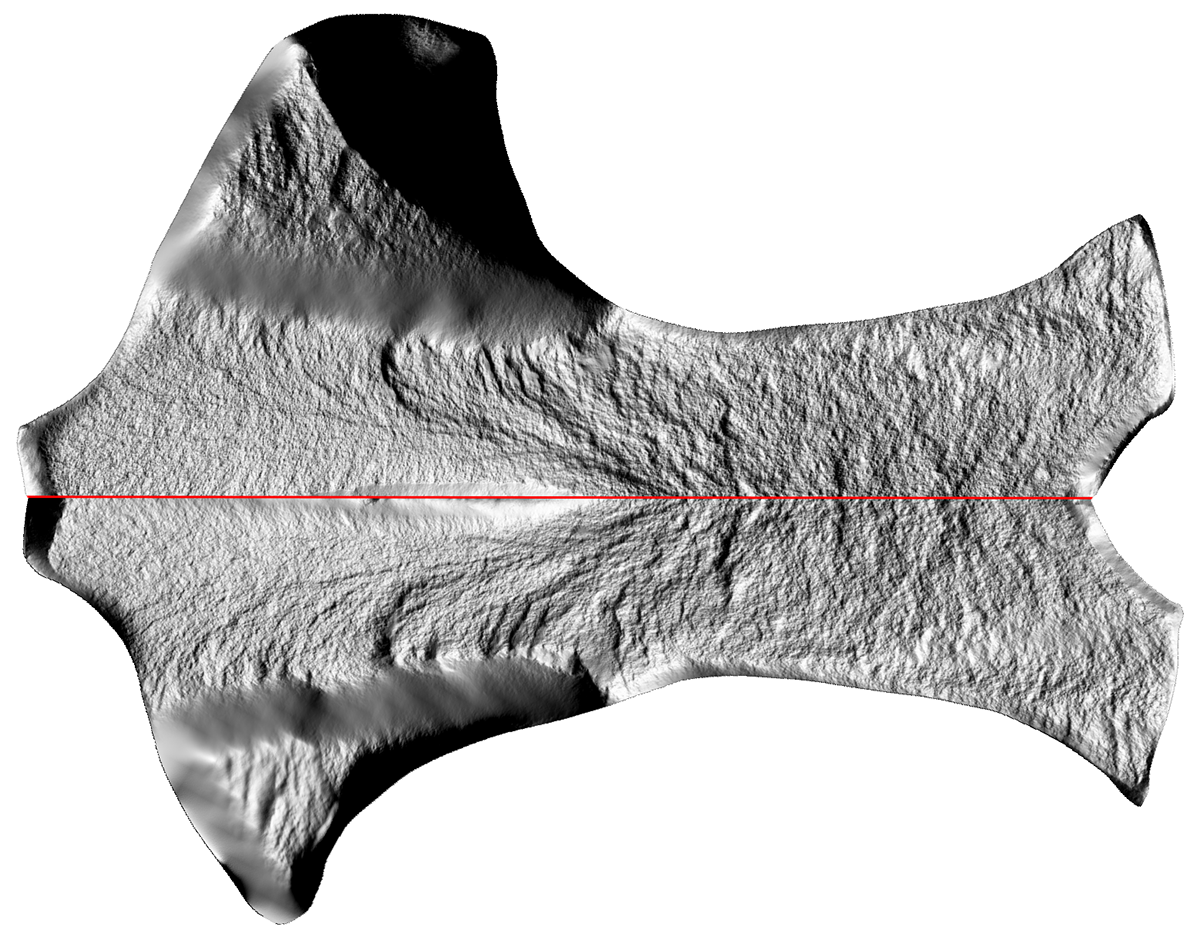

Comparison of cylinder locks toolmarks

Comparison of parts of a broken drill

Price On Application

The ToolScan System by Laboratory Imaging offers a comprehensive solution for the forensic examination of tool marks. It is designed to provide live, real-time imaging and high-resolution, all-in-focus scanning of 2D and 3D images created from focus variation combined with photometric stereo.

The key advantage of the ToolScan System is its advanced forensic software, LUCIA, which is continuously updated with new features for forensic analysis.

A 5 MP colour CMOS camera can be integrated into ToolScan to enable colour surface visualization. This feature is particularly beneficial for applications such as:

Archaeology – Identify material differences and surface details with greater clarity

Document Examination – Detect alterations, inks, and other important details.

Tool Mark Examination – Enhance the analysis of tool marks by colour differentiation.

Ballistics – Examine materials penetrated by projectiles in greater detail.

With a broad range of accessories, ToolScan can digitize various types of samples:

Toolmarks – striations, imprints, cuts, casts, and physical matching.

Tools and test samples – direct scanning of blades, cylinder locks, plier jaws, and test impressions in lead.

Documents – signatures (line intersections).

Archaeological samples – toolmarks on bones, ceramics, and other biological material.

ToolScan can be enhanced with ballistic analysis software. This allows the system to be used for ballistic examination, providing a versatile and effective alternative to the comparison microscope.

Cartridge Case Holder – for one cartridge case or special 16-CC holder for batch scanning.

Rotary Motor – enables fast, precise full-surface scanning of bullets, capturing detailed markings and characteristics.

The LUCIA Forensic software offers an intuitive workflow with multiple 2D, 3D, and texture-free comparison modes:

Users can adjust angle, intensity, and position of the light on scanned images. The light can also be synchronized across images, simulating the behaviour of a traditional comparison microscope. Users can capture screenshots of overlapping images or perform live toolmark examinations in real time.

Distinctive mechanoscopic features, such as striations, impressions, and fracture areas can be identified and marked on the digitized evidence. Using advanced algorithms and 3D data from defined toolmark areas, the software automatically aligns images, allowing experts to quickly identify similarities and accelerate comparisons.

The LUCIA Forensic software is designed to guide you step by step through the entire process, from scanning and comparing to searching the database for matching details in the samples and also publication of reports.

Beyond its primary forensic purpose, ToolScan has also proven to be a powerful instrument in archaeological research. Its highly detailed 2D and 3D images enable high-quality digital documentation of artifacts, including coins, fibulae, working tools, weapons, bones, and the toolmarks found on them.

The LUCIA ToolScan software has implemented its own module for search in a database or in a folder structure on a network drive or a local disk. It uses 3D data correlation to analyze characteristic areas of the digitized evidence. This search module provides the user with a hit list of potential matches based on the correlation score.

The ToolScan system offers a fully customizable structure that can be designed as a solution for small laboratories or scaled into a national system with a central database connected to multiple regional databases across the country. Built on an Oracle Database, ToolScan provides administrator tools to monitor system performance and access database history, enabling users to review audit information efficiently.

Cartridge case bottom captured by a colour camera (left). Cartridge case bottom (middle). Scanned bullet and processed in ballistic SW (right).

Comparison of cylinder locks toolmarks

Comparison of parts of a broken drill

ToolScan 2D and 3D toolmark imaging and comparison